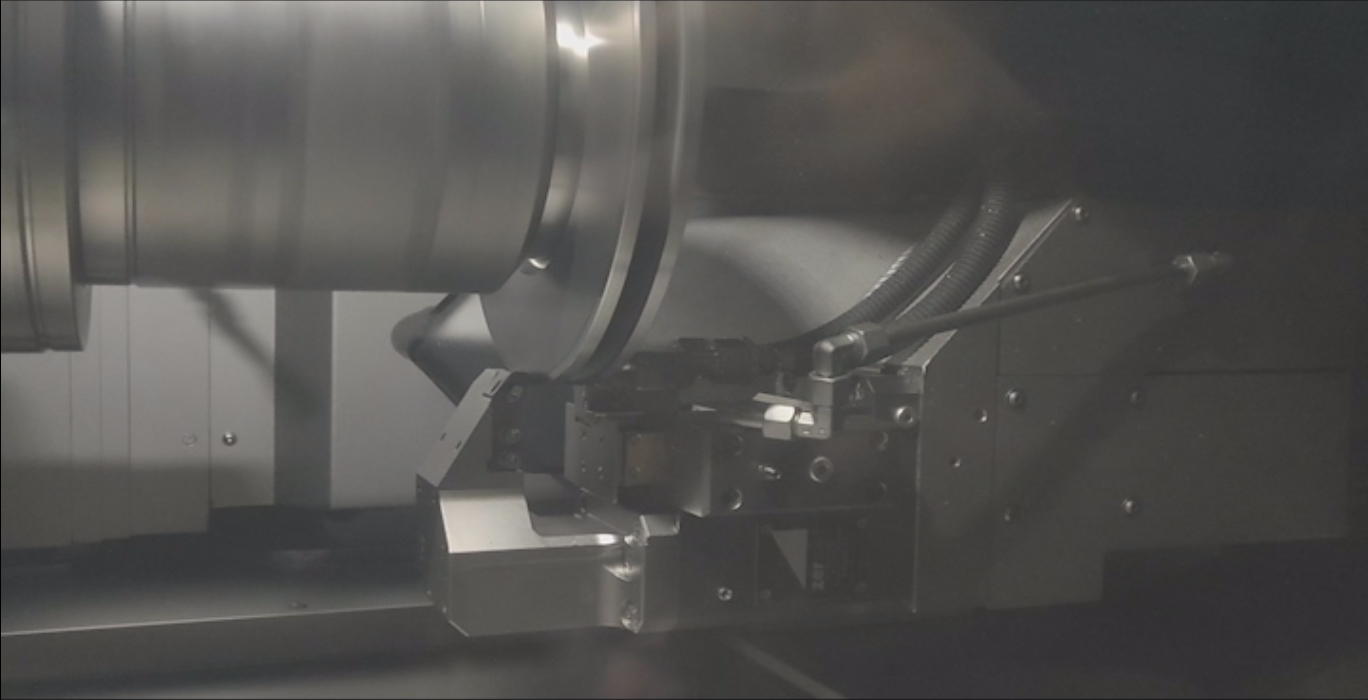

CNC Cutting Tools

CNC Cutting Tools

Agricultural knives

Agricultural knives

About Songlan

Ningbo Zhongji Songlan Tool Technology Co., Ltd.It is mainly engaged in the research and development of superhard cutting tools and the research and development, processing and testing of functional coatings on metal surfaces, and owns a number of domestic and foreign patents, has a professional technology research and development service team, and is one of the first batch of manufacturing innovation centers set up in Ningbo City. Songlan now has 6000m2 of scientific research, office and experimental space, and has purchased more than 100 sets of scientific research and production equipment with an original value of more than 50 million yuan, including Agathon peripheral grinding machine, ZEISS scanning electron microscope, KEYENCE super depth-of-field microscope, Gerber passivation machine, plasma spraying, supersonic flame spraying, laser cladding, plasma arc welding, CMT welding and other international advanced precision processing and welding. Welding and other internationally advanced precision machining and testing equipment and instruments, the products cover a variety of series such as cubic boron nitride ultra-precision cutting tools, integral polycrystalline tools, super welding polycrystalline tools, etc., which are widely used in aerospace, military, automotive, precision manufacturing and other high-end processing fields.

View Details

About Songlan

Ningbo Zhongji Songlan Tool Technology Co., Ltd.It is mainly engaged in the research and development of superhard cutting tools and the research and development, processing and testing of functional coatings on metal surfaces, and owns a number of domestic and foreign patents, has a professional technology research and development service team, and is one of the first batch of manufacturing innovation centers set up in Ningbo City. Songlan now has 6000m2 of scientific research, office and experimental space, and has purchased more than 100 sets of scientific research and production equipment with an original value of more than 50 million yuan, including Agathon peripheral grinding machine, ZEISS scanning electron microscope, KEYENCE super depth-of-field microscope, Gerber passivation machine, plasma spraying, supersonic flame spraying, laser cladding, plasma arc welding, CMT welding and other international advanced precision processing and welding. Welding and other internationally advanced precision machining and testing equipment and instruments, the products cover a variety of series such as cubic boron nitride ultra-precision cutting tools, integral polycrystalline tools, super welding polycrystalline tools, etc., which are widely used in aerospace, military, automotive, precision manufacturing and other high-end processing fields.

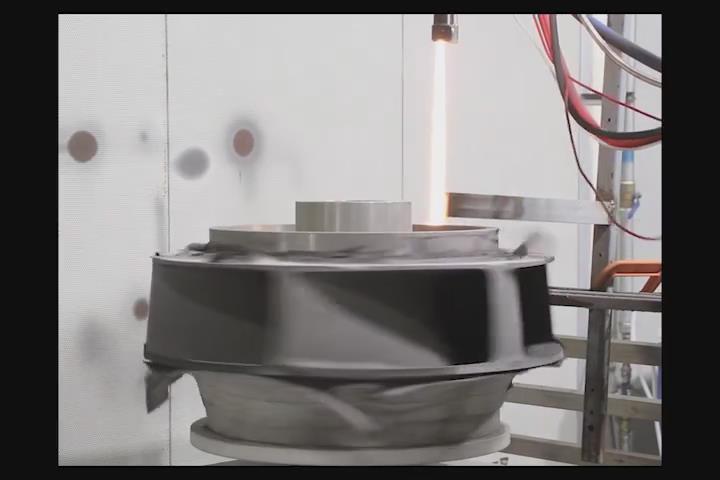

View DetailsA wear-resistant coating was prepared on the surface of the throwing knife blade using laser cladding technology, followed by quenching, increasing the service life by more than two times.

This product uses laser cladding technology to prepare a tungsten carbide Ni-based powder composite wear-resistant coating on its surface. The tungsten carbide proportion is about 50wt%, and the coating hardness reaches 64HRC; the coating shape extends inward from the outer contour of the product in multiple passes, the coating width is about 3mm, and the thickness is about 0.2mm. Field tests show that the service life of the laser cladding tungsten carbide composite coating mixer blade is more than three times that of the original product.

Producing wear-resistant coatings on the surface of shaft parts using laser cladding technology.

A plasma cladding process was used to prepare a ferrous wear-resistant coating on the surface of the hammer, with a coating thickness of 2mm, increasing the service life by 1.5 times.

A diamond wear-resistant coating was prepared on the back of the lawn mower blade, doubling its service life.

A diamond composite wear-resistant coating with a thickness of approximately 0.2mm and a diamond content exceeding 10wt% is applied to the working area of the carding knife. This type of knife has a lifespan that can be increased by more than three times. Even after wear, it still exhibits better carding performance than other blades.

A diamond wear-resistant coating was prepared on the back of the knife blade, followed by quenching, increasing its service life by more than two times.

The blade surface has a diamond wear-resistant coating. The coating is uniform in thickness, significantly improving wear resistance and extending service life by more than 3 times.

Diamond wear-resistant coatings are prepared on the surface of the sheet material, doubling the service life of the sheet material.